-

English

-

Español

-

Português

-

Русский

-

Français

-

日本語

-

Deutsch

-

Tiếng Việt

-

Italiano

-

Nederlands

-

ไทย

-

Polski

-

한국어

-

Svenska

-

Magyar

-

Bahasa Melayu

-

বাংলা

-

Dansk

-

Suomi

-

हिन्दी

-

Filipino

-

Türkçe

-

Gaeilge

-

العربية

-

Bahasa Indonesia

-

Norsk

-

اردو

-

Čeština

-

Ελληνικά

-

Українська

-

Basa Jawa

-

فارسی

-

தமிழ்

-

తెలుగు

-

नेपाली

-

မြန်မာ

-

Български

-

ລາວ

-

Latina

-

Қазақша

-

Euskera

-

Azərbaycan

-

Slovenčina

-

Македонски

-

Lietuvių

-

Eesti

-

Română

-

Slovenščina

Home

>

Products

>

Induction Heating Equipment

>

Induction Heating Equipment For Rolling

>

Steel Ball Rolling Mill with Integrated Heating System

Categories

-

Induction Heating Equipment

- Induction Heating Equipment for Make-up Heating

- Induction Heating Equipment For Rolling

- Induction Heating Equipment for Plates

- Induction Heating Equipment for Pre-forging

- Induction Heating Equipment for Aluminum Rods

- Induction Heating Equipment for Titanium Rods

- Induction Heating Equipment for Copper Rods

- Induction Heat Treatment Line

- Induction Quenching and Tempering Line

- Induction Hardening Line

Steel Ball Rolling Mill with Integrated Heating System

Yuantuo steel ball rolling heating equipment adopts medium-frequency induction heating technology and is specifically designed for steel ball production lines. It is widely used for rolling heating of carbon steel, alloy steel, and other steel materials. Through a highly efficient induction heating process, this equipment ensures that the steel balls reach the required ideal temperature before rolling, significantly improving production efficiency and product quality.

Send Inquiry

Product Description

Yuantuo steel ball rolling heating equipment adopts medium-frequency induction heating technology and is specifically designed for steel ball production lines. It is widely used for rolling heating of carbon steel, alloy steel, and other steel materials. Through a highly efficient induction heating process, this equipment ensures that the steel balls reach the required ideal temperature before rolling, significantly improving production efficiency and product quality.

Product Feature

System Features

High-Efficiency Heating:

Yuantuo's steel ball rolling heating equipment utilizes advanced medium-frequency induction heating technology to rapidly heat steel balls to the required temperature, ensuring uniform temperature distribution throughout the heating process. Precise temperature control prevents localized overheating or uneven heating, thus guaranteeing high-quality steel balls.

Energy Saving and Environmental Protection:

Employing a high-efficiency medium-frequency power supply and a modular furnace design significantly improves heating efficiency and reduces energy consumption. The equipment features low harmonics and a high power factor (≥0.90), reducing grid load and harmonic pollution.

Precise Temperature Control and Automation:

The equipment is equipped with a PLC automatic control system that monitors the heating temperature of each steel ball in real time using an infrared thermometer. The system automatically adjusts the power output based on real-time temperature data, ensuring the steel balls reach the precise heating temperature before rolling, with a temperature difference controlled within ±10 degrees Celsius.

Intelligent Operation and Easy Management:

The entire production process is automatically controlled by the PLC system. Operators can monitor equipment status and adjust process parameters in real time via a touchscreen. The equipment has a fault alarm function and automatically records production data, improving ease of operation and equipment management efficiency.

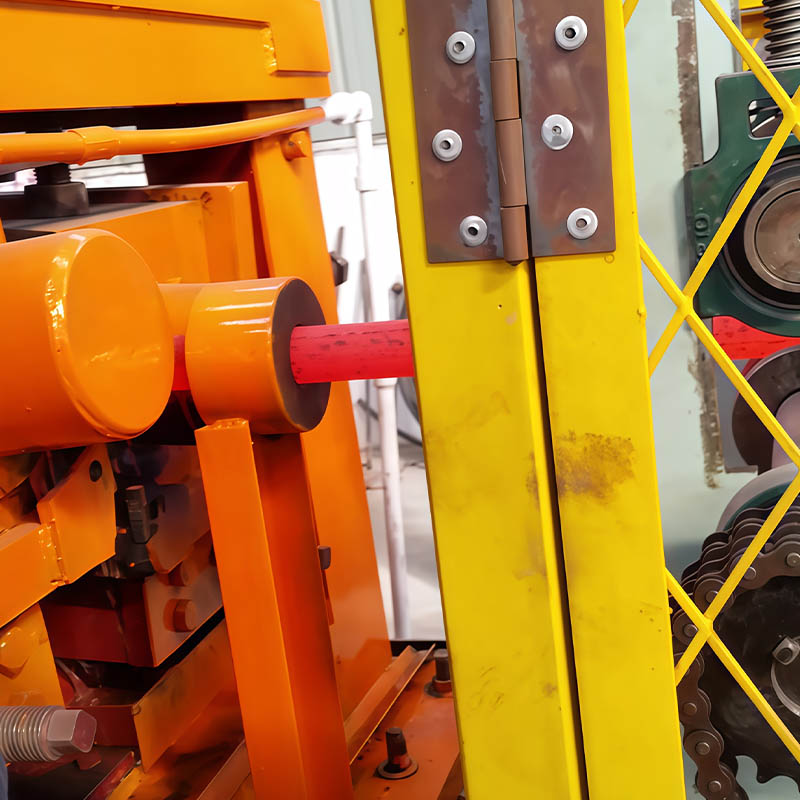

Modular Furnace Design:

The furnace body adopts a modular design, supporting quick replacement and installation. Depending on the specifications of the steel balls, the equipment can be flexibly configured with inductors and heating modules to meet various production needs, improving the flexibility and efficiency of the production line.

Applications

Yuantuo steel ball rolling heating equipment is widely applicable to the following industries:

● Steel ball manufacturing: Used for heating steel balls of various sizes and materials, suitable for producing high-strength, high-hardness steel balls.

● Machinery manufacturing: Improves the strength, wear resistance, and service life of mechanical parts.

● Mining and metallurgical industry: Used for the production of wear-resistant steel balls, especially in mineral processing and ball milling processes.

Heating and Processing Technology

Steel Ball Heating

The steel balls are rapidly heated to the required temperature using a medium-frequency induction heating furnace. During the heating process, the current frequency and power are automatically adjusted according to the material and size of the steel balls to ensure uniform heating and avoid surface overheating or localized underheating.

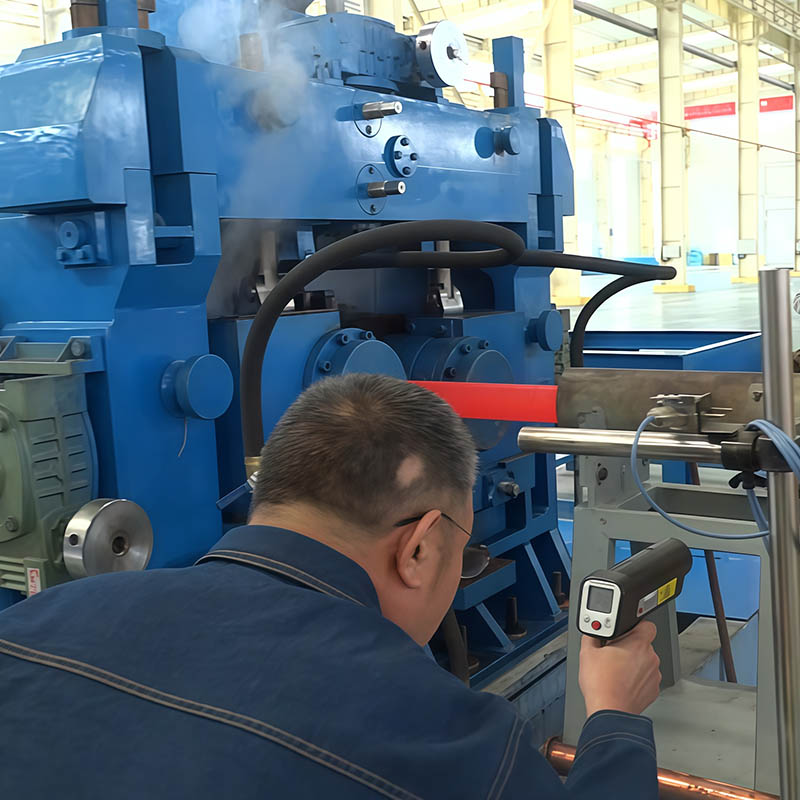

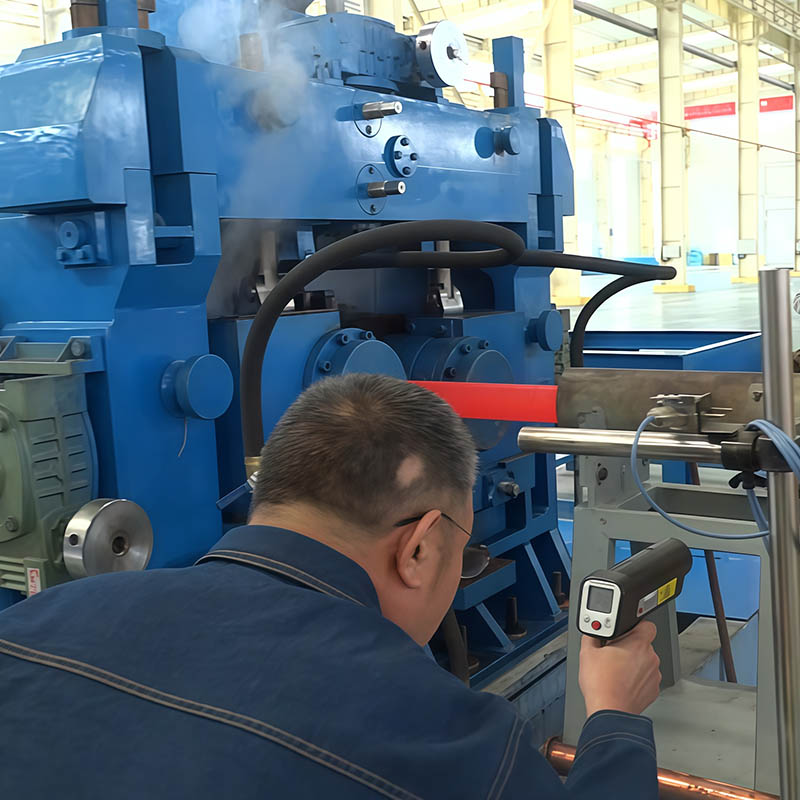

Temperature Monitoring and Control

Equipped with an infrared thermometer, the surface temperature of the steel balls is monitored in real time and the data is transmitted to the PLC system. Based on temperature data, the PLC system automatically adjusts the power supply to ensure stable temperature during heating and prevent excessive temperature differences.

Intelligent Operation

The equipment's operation interface is displayed in real-time via the PLC system. Operators can easily view real-time parameters such as temperature and power, and make adjustments to the equipment. The system can record production data and heating curves, and generate temperature data reports as needed, supporting USB flash drive data storage and historical retrieval.

Temperature Control Monitoring and Automatic Adjustment

Precise Temperature Control

Through infrared temperature measurement and PLC system linkage, the equipment achieves precise heating temperature control, maintaining uniform heating of the steel balls and avoiding quality problems caused by uneven heating.

Automatic Adjustment Function

The equipment can automatically adjust the heating power according to the size and material of the steel balls, ensuring that each steel ball reaches the ideal heating temperature before entering the rolling stage.

Automatic Discharge and Cooling

Automatic Discharge System

Heated steel balls enter the cooling zone through an automated discharge system. The cooling process is controlled by the PLC system to ensure uniform cooling of the steel balls.

Cooling System

Equipped with a high-efficiency cooling system, the cooling tower and cooling water tank efficiently cool the steel balls and reduce energy consumption. By precisely controlling the flow rate, temperature, and pressure of the cooling water, the quality of the steel balls is fully guaranteed.

High-Efficiency Heating:

Yuantuo's steel ball rolling heating equipment utilizes advanced medium-frequency induction heating technology to rapidly heat steel balls to the required temperature, ensuring uniform temperature distribution throughout the heating process. Precise temperature control prevents localized overheating or uneven heating, thus guaranteeing high-quality steel balls.

Energy Saving and Environmental Protection:

Employing a high-efficiency medium-frequency power supply and a modular furnace design significantly improves heating efficiency and reduces energy consumption. The equipment features low harmonics and a high power factor (≥0.90), reducing grid load and harmonic pollution.

Precise Temperature Control and Automation:

The equipment is equipped with a PLC automatic control system that monitors the heating temperature of each steel ball in real time using an infrared thermometer. The system automatically adjusts the power output based on real-time temperature data, ensuring the steel balls reach the precise heating temperature before rolling, with a temperature difference controlled within ±10 degrees Celsius.

Intelligent Operation and Easy Management:

The entire production process is automatically controlled by the PLC system. Operators can monitor equipment status and adjust process parameters in real time via a touchscreen. The equipment has a fault alarm function and automatically records production data, improving ease of operation and equipment management efficiency.

Modular Furnace Design:

The furnace body adopts a modular design, supporting quick replacement and installation. Depending on the specifications of the steel balls, the equipment can be flexibly configured with inductors and heating modules to meet various production needs, improving the flexibility and efficiency of the production line.

Applications

Yuantuo steel ball rolling heating equipment is widely applicable to the following industries:

● Steel ball manufacturing: Used for heating steel balls of various sizes and materials, suitable for producing high-strength, high-hardness steel balls.

● Machinery manufacturing: Improves the strength, wear resistance, and service life of mechanical parts.

● Mining and metallurgical industry: Used for the production of wear-resistant steel balls, especially in mineral processing and ball milling processes.

Heating and Processing Technology

Steel Ball Heating

The steel balls are rapidly heated to the required temperature using a medium-frequency induction heating furnace. During the heating process, the current frequency and power are automatically adjusted according to the material and size of the steel balls to ensure uniform heating and avoid surface overheating or localized underheating.

Temperature Monitoring and Control

Equipped with an infrared thermometer, the surface temperature of the steel balls is monitored in real time and the data is transmitted to the PLC system. Based on temperature data, the PLC system automatically adjusts the power supply to ensure stable temperature during heating and prevent excessive temperature differences.

Intelligent Operation

The equipment's operation interface is displayed in real-time via the PLC system. Operators can easily view real-time parameters such as temperature and power, and make adjustments to the equipment. The system can record production data and heating curves, and generate temperature data reports as needed, supporting USB flash drive data storage and historical retrieval.

Temperature Control Monitoring and Automatic Adjustment

Precise Temperature Control

Through infrared temperature measurement and PLC system linkage, the equipment achieves precise heating temperature control, maintaining uniform heating of the steel balls and avoiding quality problems caused by uneven heating.

Automatic Adjustment Function

The equipment can automatically adjust the heating power according to the size and material of the steel balls, ensuring that each steel ball reaches the ideal heating temperature before entering the rolling stage.

Automatic Discharge and Cooling

Automatic Discharge System

Heated steel balls enter the cooling zone through an automated discharge system. The cooling process is controlled by the PLC system to ensure uniform cooling of the steel balls.

Cooling System

Equipped with a high-efficiency cooling system, the cooling tower and cooling water tank efficiently cool the steel balls and reduce energy consumption. By precisely controlling the flow rate, temperature, and pressure of the cooling water, the quality of the steel balls is fully guaranteed.

Send Inquiry

Please Feel free to give your inquiry in the form below. We

will

reply you in 24 hours.