-

English

-

Español

-

Português

-

Русский

-

Français

-

日本語

-

Deutsch

-

Tiếng Việt

-

Italiano

-

Nederlands

-

ไทย

-

Polski

-

한국어

-

Svenska

-

Magyar

-

Bahasa Melayu

-

বাংলা

-

Dansk

-

Suomi

-

हिन्दी

-

Filipino

-

Türkçe

-

Gaeilge

-

العربية

-

Bahasa Indonesia

-

Norsk

-

اردو

-

Čeština

-

Ελληνικά

-

Українська

-

Basa Jawa

-

فارسی

-

தமிழ்

-

తెలుగు

-

नेपाली

-

မြန်မာ

-

Български

-

ລາວ

-

Latina

-

Қазақша

-

Euskera

-

Azərbaycan

-

Slovenčina

-

Македонски

-

Lietuvių

-

Eesti

-

Română

-

Slovenščina

-

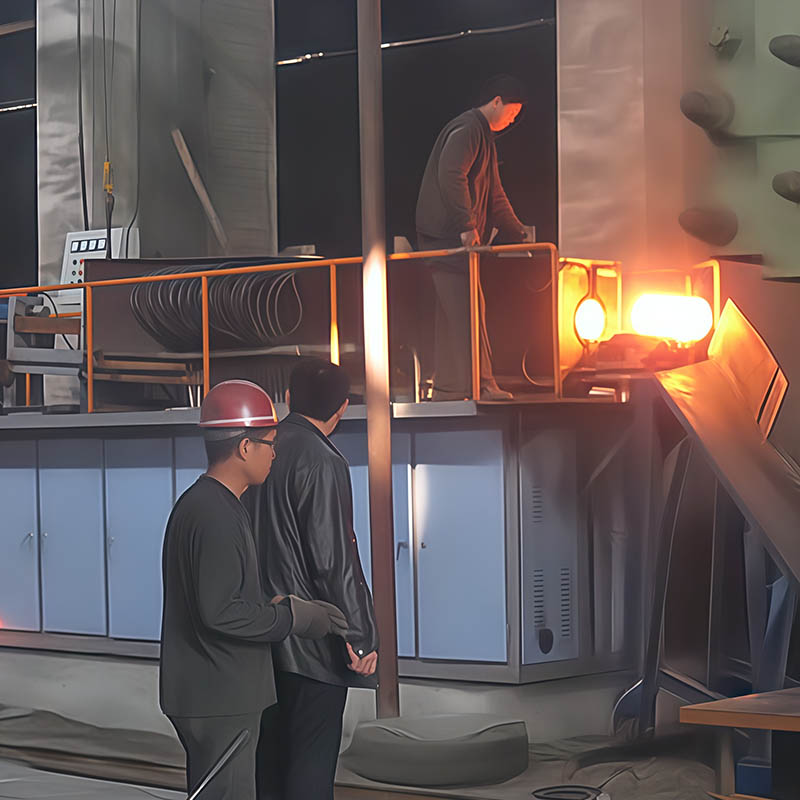

Induction Heating Equipment

- Induction Heating Equipment for Make-up Heating

- Induction Heating Equipment For Rolling

- Induction Heating Equipment for Plates

- Induction Heating Equipment for Pre-forging

- Induction Heating Equipment for Aluminum Rods

- Induction Heating Equipment for Titanium Rods

- Induction Heating Equipment for Copper Rods

- Induction Heat Treatment Line

- Induction Quenching and Tempering Line

- Induction Hardening Line

Steel Rod Heating Equipment

Designed and manufactured by Hebei Yuantuo Electromechanical Equipment Manufacturing Co., Ltd., the electromechanical integrated induction heating system is specifically designed for through-heating forging of metal materials such as bars and round bars, providing an efficient and stable solution for through-heating forging of bars and round bars

Send Inquiry

Category | Specific parameters |

Power supply system | Power range: 200KW-3000KW / 500Hz-4000Hz. The system adopts an electromechanical integrated design, which can provide flexible power configuration options for various production scales and ensure a highly efficient and stable heating process. |

Applicable materials | The materials that can be heated include: carbon steel, alloy steel, high-temperature alloy steel, antimagnetic steel, stainless steel, titanium, aluminum alloy, and copper alloy; it is suitable for heating a variety of metal materials and meets different forging requirements. |

Main uses | This system is mainly used for through-heating forging of bars and round steel, ensuring that the ideal heating state is achieved before forging, thereby improving the accuracy and efficiency of subsequent processing. |

Equipped with a fully automatic corrugated plate feeder, it efficiently and accurately feeds workpieces into the heating zone, ensuring a stable and uninterrupted feeding process.

2. Feeding System:

Double-roller pneumatic pressurization ensures continuous feeding of workpieces during heating. The feed speed is adjustable via stepless speed control, providing flexible adjustment options to adapt to different process requirements.

3. Discharge System:

Equipped with a chain conveyor system, it ensures that heated workpieces can be efficiently and quickly transferred to the next production stage, improving the overall efficiency of the production line.

4. Sorting System:

Composed of an infrared thermometer, chain conveyor system, and guide cylinders, it monitors workpiece temperature in real time and ensures accurate transfer and sorting of workpieces during production, improving temperature control accuracy.