-

English

-

Español

-

Português

-

Русский

-

Français

-

日本語

-

Deutsch

-

Tiếng Việt

-

Italiano

-

Nederlands

-

ไทย

-

Polski

-

한국어

-

Svenska

-

Magyar

-

Bahasa Melayu

-

বাংলা

-

Dansk

-

Suomi

-

हिन्दी

-

Filipino

-

Türkçe

-

Gaeilge

-

العربية

-

Bahasa Indonesia

-

Norsk

-

اردو

-

Čeština

-

Ελληνικά

-

Українська

-

Basa Jawa

-

فارسی

-

தமிழ்

-

తెలుగు

-

नेपाली

-

မြန်မာ

-

Български

-

ລາວ

-

Latina

-

Қазақша

-

Euskera

-

Azərbaycan

-

Slovenčina

-

Македонски

-

Lietuvių

-

Eesti

-

Română

-

Slovenščina

-

Induction Heating Equipment

- Induction Heating Equipment for Make-up Heating

- Induction Heating Equipment For Rolling

- Induction Heating Equipment for Plates

- Induction Heating Equipment for Pre-forging

- Induction Heating Equipment for Aluminum Rods

- Induction Heating Equipment for Titanium Rods

- Induction Heating Equipment for Copper Rods

- Induction Heat Treatment Line

- Induction Quenching and Tempering Line

- Induction Hardening Line

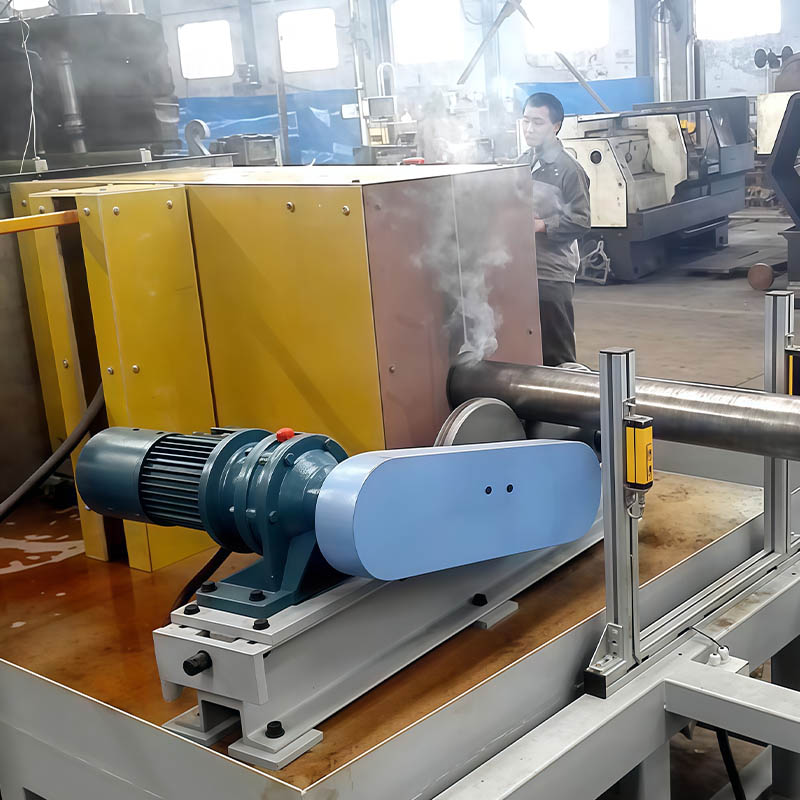

Steel Pipe Heat Treatment Line

The Steel Pipe Heat Treatment Line is suitable for quenching and tempering heat treatment of steel pipes, low-carbon alloy steel, wind turbine bolts, anchor bolts, lead screws, and hydraulic cylinder rods. It provides high-quality quenching and tempering treatments with high productivity and precise control.

Send Inquiry

Category | Specific parameters |

Power supply system - quenching | 160KW - 3000KW / 0.5 - 4kHz |

Power supply system - backfire | 200KW - 3000KW / 0.5 - 2.5kHz |

Yield | 1.5-10 tons/hour |

Scope of application | 20-150mm |

Conveyor roller conveyor | The roller conveyor axis forms a certain angle with the working axis, ensuring that the workpiece rotates and is fed at a uniform speed during the conveying process, thus ensuring more uniform heating. The roller conveyor in the furnace body is made of 304 non-magnetic stainless steel and undergoes water cooling treatment; the roller conveyor in other parts is made of 45 steel and surface hardened. |

Roller conveyor grouping | The roller conveyor is divided into a feeding group, an induction heating group, and a discharging group, each of which is independently controlled. This helps to achieve continuous heating and avoid gaps between workpieces. |

Temperature closed-loop control | During the quenching and tempering processes, an infrared thermometer and a PLC system are used to form a closed-loop control system to precisely control the temperature. |

Industrial control computer system | It displays current working parameters in real time, records, stores, and prints workpiece parameters, and has fault display and alarm functions to ensure operational safety. |

● High Productivity: The production line can process 0.5 to 5 tons of product per hour, meeting the needs of medium to large-scale production.

● High-Efficiency Heating: A uniform and precise temperature control system reduces energy loss and improves heating quality.

● Energy Efficiency: The modern medium-frequency induction heating system has a high power factor, effectively reducing energy consumption.

● Easy Operation: An advanced temperature control and equipment management system simplifies operation and maintenance.