We provide stable and efficient induction heat

treatment solutions for metallic materials

-

English

-

Español

-

Português

-

Русский

-

Français

-

日本語

-

Deutsch

-

Tiếng Việt

-

Italiano

-

Nederlands

-

ไทย

-

Polski

-

한국어

-

Svenska

-

Magyar

-

Bahasa Melayu

-

বাংলা

-

Dansk

-

Suomi

-

हिन्दी

-

Filipino

-

Türkçe

-

Gaeilge

-

العربية

-

Bahasa Indonesia

-

Norsk

-

اردو

-

Čeština

-

Ελληνικά

-

Українська

-

Basa Jawa

-

فارسی

-

தமிழ்

-

తెలుగు

-

नेपाली

-

မြန်မာ

-

Български

-

ລາວ

-

Latina

-

Қазақша

-

Euskera

-

Azərbaycan

-

Slovenčina

-

Македонски

-

Lietuvių

-

Eesti

-

Română

-

Slovenščina

Home

>

مصنوعات

>

انڈکشن حرارتی سامان

>

رولنگ کے لئے حرارتی سامان شامل کرنا

>

Heating Equipment for Steel Rod Rolling

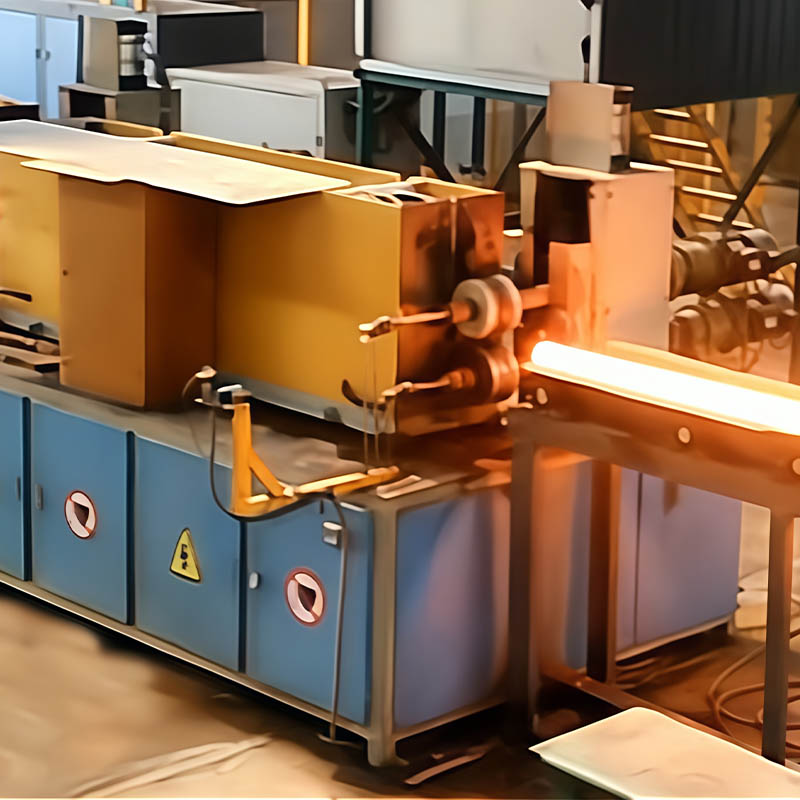

Heating Equipment for Steel Rod Rolling

Designed and manufactured by Hebei Yuantuo Electromechanical Equipment Manufacturing Co., Ltd., the induction heating system for rolling mills is specifically designed for heating and rolling metal materials such as rebar, die steel, and stainless steel. This system utilizes advanced induction heating technology, enabling efficient heating of steel of different specifications and ensuring temperature uniformity and efficiency during the rolling process.

Send Inquiry

Product Description

Designed and manufactured by Hebei Yuantuo Electromechanical Equipment Manufacturing Co., Ltd., the induction heating system for rolling mills is specifically designed for heating and rolling metal materials such as rebar, die steel, and stainless steel. This system utilizes advanced induction heating technology, enabling efficient heating of steel of different specifications and ensuring temperature uniformity and efficiency during the rolling process.

Product Parameter

Category | Specific parameters |

Power supply system - power range | 1000KW-5000KW |

Power supply system - frequency range | 2.5kHz-15kHz |

Power supply system - Specifications | Φ12-Φ32 |

Hourly output | 2.5-15 tons, to meet the needs of different production scales. |

Applicable raw materials | M2 high-speed steel, 11Cr17 martensitic stainless steel, rebar |

Product Feature

1. High-Efficiency Induction Heating Design:

The inductor design employs variable turn spacing and temperature gradient design, maximizing heating efficiency and workpiece uniformity, providing ideal heating conditions for subsequent rolling.

2. Flexible Adjustable Pressure Rollers:

Equipped with flexible adjustable pressure rollers, ensuring uniform feeding of round steel bars of different diameters, effectively avoiding uneven heating caused by inconsistent workpiece diameters. The roller conveyor and pressure rollers between furnace bodies are made of 304 non-magnetic stainless steel and equipped with a water-cooling system to ensure stable operation in high-temperature environments.

3. Precise Temperature Control System:

An infrared temperature measuring device is installed at the discharge end to monitor the temperature of the steel bars in real time, ensuring a consistent temperature before the steel bars enter the rolling mill, thereby improving the stability and quality of the rolling process.

The inductor design employs variable turn spacing and temperature gradient design, maximizing heating efficiency and workpiece uniformity, providing ideal heating conditions for subsequent rolling.

2. Flexible Adjustable Pressure Rollers:

Equipped with flexible adjustable pressure rollers, ensuring uniform feeding of round steel bars of different diameters, effectively avoiding uneven heating caused by inconsistent workpiece diameters. The roller conveyor and pressure rollers between furnace bodies are made of 304 non-magnetic stainless steel and equipped with a water-cooling system to ensure stable operation in high-temperature environments.

3. Precise Temperature Control System:

An infrared temperature measuring device is installed at the discharge end to monitor the temperature of the steel bars in real time, ensuring a consistent temperature before the steel bars enter the rolling mill, thereby improving the stability and quality of the rolling process.

Send Inquiry

Please Feel free to give your inquiry in the form below. We

will

reply you in 24 hours.